Japanese Knife, Deba and Sashimi

There are several kinds of Japanese traditional knives. Most of Japanese knives are single-edged. Flat on one side and edged on the other. If you are an angler and want to enjoy the art of preparing your catch, the ones you want are Deba knife and Sashimi knife. They are both single-edged.

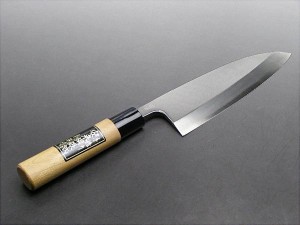

Deba Knife

Deba Knife is a thick heavy knife to cut the fish into fillets. The common blade is 15cm to 21cm long. The blade spine is thick and the weight of the knife helps to cut through bones. (Use the handle side of the blade belly.)

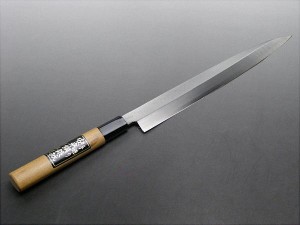

Sashimi Knife

Sashimi knife is the longest knife. The blade is usually 20 to 35cm. It is for the beautiful sashimi cut by one long one-way stroke. You are not supposed to go back until you complete the slice. Sashimi slices can be really thin sometimes. The blade is thin and light for better control.

Material of Japanese Blades

Japanese steel is highly purified iron, produced from iron sand by the traditional technique which is used to make Japanese sword as well.

SK Steel

SK Steel is the common carbon steel. It’s used widely as a common industrial material for saws, axes and other blades.

Yellow Steel

Yellow Steel is the purified iron steel, by removing impurities like silicon, phosphorus and sulfur out of SK Steel. This is no professional use. Economical knives for home use. But it is Japanese forged iron, and it’s much sharper than stainless steel knife. It contains carbon 1.00% to 1.20%.

White Steel

White Steel is the most purified iron of all. They purify iron sand to remove the impurities to the utmost limit with no additions to come up with White Steel #2. It requires highly skilled craftsmen to produce blades with White Steel and Blue Steel.

When it’s produced, White Steel #2 is the most balanced properties of sharpness, edge retention, and easiness to sharpen. It contains carbon 1.00% to 1.20%, but less impurities than in Yellow Steel. This is a very good entry steel for professionals and devoted anglers. Like they say, the quality of the knife improves chefs skills. The price range of 150mm Deba knife with this steel is about JPY15,000 to 25,000. (Sometimes over JPY50,000)

White Steel #3 has less carbon (0.80% to 0.90%). Yellow Steel is harder than White Steel #3 (more carbon), but White Steel has less impurities, therefore, better sharpness. It’s easier to sharpen than #2. And cheaper. The price range of 150mm Deba knife with this steel is about JPY5,000 to 15,000. When it says just White Steel, it’s very likely to be this steel. If you can’t afford White Steel #2, #3 is your option.

White Steel #1 has more carbon (1.30 to 1.40%). The hardest and the sharpest White Steel. It is the closest steel to make the Japanese sword. It requires extremely high skills to produce blades with this steel. And the same goes to the user as well. It’s easy to be chipped and rust.

But the sharpness is extraordinary. The exotic masterpiece can be made of this steel. The price range of 150mm Deba knife with this steel is about JPY20,000 to 50,000. (Sometimes over JPY100,000)

Blue Steel

White Steel #2 with chrome and tungsten added becomes Blue Steel #2. The ideal knife would be super sharp, hold edge for long, and be easy to sharpen. Blue Steel is the alloy in efforts for that ideal. Blue Steel #1 has more carbon, chrome and tungsten, less others. Super Blue Steel is even more purified carbon, but with vanadium and molybdenum added for more lasting sharpness.

Blue Steel the most expensive category, but the closest to the ideal knife. It is virtually the Japanese sword by the modern technology and the finest craftsmen.

However, in general, Blue Steel is still hard to sharpen. It’s so hard. That is also why the sharpening is not required as frequently as other steels. But it takes skills and experience of sharpening this blade, along with a series of proper sharpening stones.

Sharpening Japanese Blades

First, let the stone soak in the water for 15 to 30 minutes.

Place the knife 45 degrees on the stone. The edged side down. The cutting edge facing toward you. The edge bevel flat on the stone.

You put the pressure down and away. You push with the pressure and release on the pull. Always check the flat side of the edge to see if you got the curve that has been scraped. Make sure you sharpen the tip as well.

Flip over and lay the flat side of the blade on the stone. Flat on the stone. And lightly, just scrape off that curve on the edge with 1 or 2 strokes.

When you’re done sharpening, wash it well with a cleanser as the immediate use may get the fish smelly of iron. Dry completely and wipe with oil to refrain from rusting.

Usually, we don’t sharpen before use, but after use.

If you want to import authentic knives from Japan, I’ll be happy to help you.

Related Posts

4 Comments

Leave a Reply Cancel reply

Categories

- 1. SPJ (57)

- 1-1. Principles (9)

- 1-2. Techniques (11)

- 1-3. Setup (17)

- 1-4. FAQ (19)

- 1-5. Tackles (3)

- 1-6. Video Gallery (2)

- 2. Other Offshore Games (5)

- 3. Fishing Report (105)

- 3-1. Totos (25)

- 3-2. Readers (72)

- 4. Fish Cooking (19)

- 4-1. Iki-Jime (3)

- 4-2. The Art of Sashimi (5)

- 4-3. Recipe (7)

- 4-4. Seasoning (3)

- 5. Fishing Charter (6)

- Fish (12)

I have had a sashimi knife for a while now and it makes a big difference when cutting super thin slices of fish. We go through so much trouble to catch our fish I think having the correct knife for the job is important and having owned one I wouldnt be without it. Out of interest Totos what knife do you use for filleting and skinning your fish ?.

I read you my friend. There’s always a right tool to do a good job.

I use my 180mm Deba to do the filleting. I’ve always wanted a shorter one and I just got myself a 135mm. For skinning, I am a ever lasting challenger for the art of “leaving the silver on”. It seems that Deba works better with some fish, and sashimi with others.

Leave the silver on

http://anglers-secrets.com/v2020/how-to-fillet-a-fish-skin-it-with-silver-on/

Hi Totos,

What is the proper grit # of the whetstone to finish the last sharpening stage for these knives; I’ve got #6000, is it enough for the job?

While watching the video, I had to close my eyes when he tested the edge on his own finger nail cause I knew very well how sharp those knives were.

Hi Kitidas.

#6000 sounds right for fine finishing.

But it really depends on what steel the knife is and what material the stone is. The makers have different standards for numbering as well. And I really don’t know enough yet.

But for our pleasure use, and generally speaking, #1000 is good enough for daily use to keep the sharpness. Doing #3000 on top of that will make it really sharper. And #6000 can refine even more. #100 to #300 is for fixing.

He’s only touching the nail. Really sharpened edge “bites and sinks in” with a light touch, he says. I don’t know how that feels really. That is a pro.